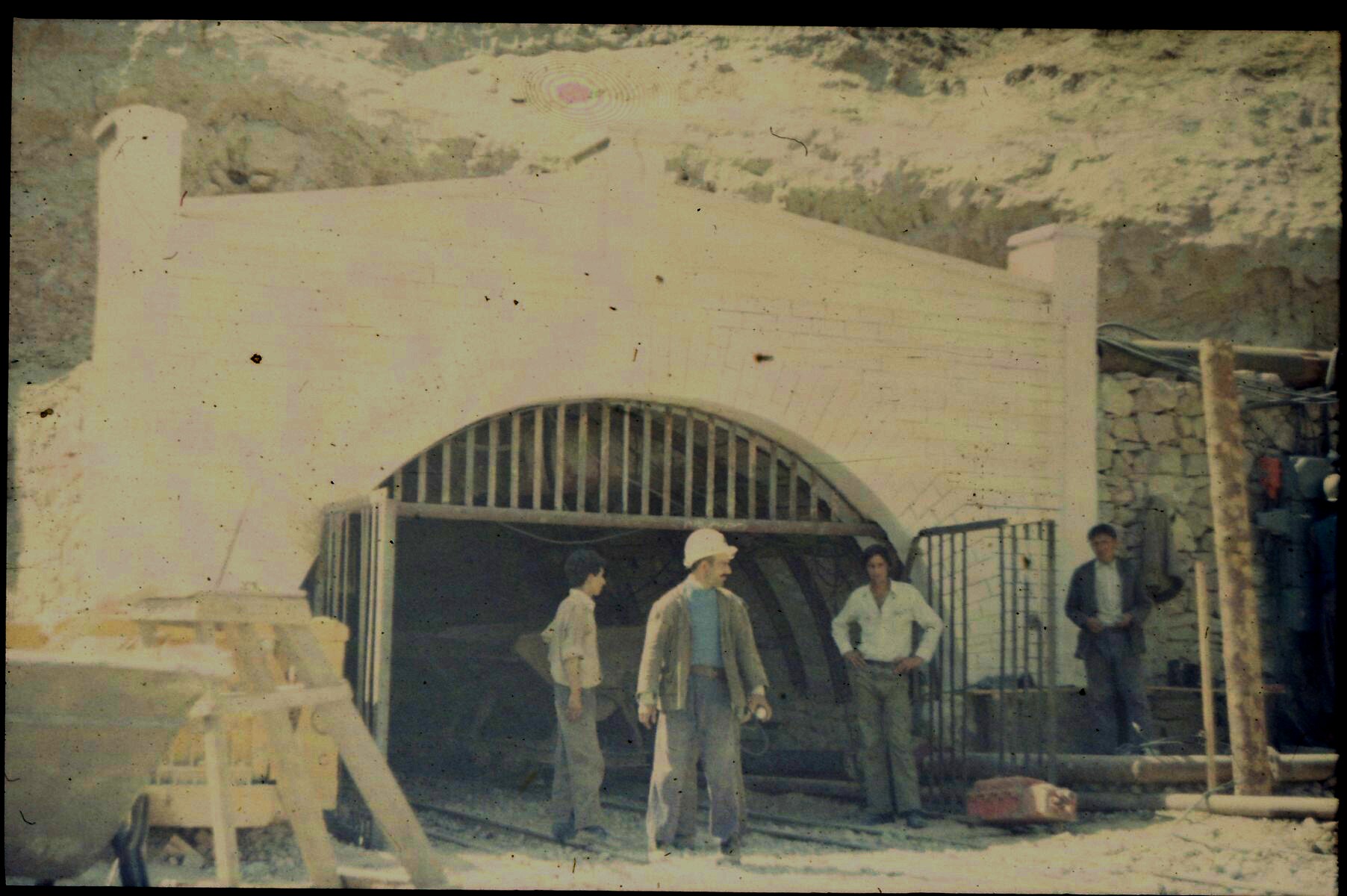

Entrance to the Karkar coal mine (Photo: US Geological Survey)

There are a handful of coal mines in Afghanistan, at least two of which have hand-worked narrow gauge railways and appear to have used locomotives in the past.

Afghanistan has had a small coal mining industry since shortly after the World War I, producing coal for the domestic market. There are three main mining centres: Darra-i-Suf south of Mazar-i-Sharif, opened in 1966, and the Karkar and Ispushta mines near Pol-e Khomri, developed in the 1950s.1

Much of the coal is relatively deep or currently inaccessible, however, and the scale of development has been limited. Indigenous coal has been used in Afghanistan for small industry (notably in the manufacturing of cement and textiles, and in food processing), and as a primary source of household fuel in both raw and briquetted forms. Electrical generation from coal has occurred only on a temporary basis when coal was used as a substitute fuel for generation by natural gas. The main factors limiting the more widespread use of coal in the past appear to have been the rugged terrain of the country, the lack of a transportation network to deliver coal, and the absence of an industrial infrastructure to utilize the coal.2

There are also various very small-scale mines operated independently (and perhaps without reporting full details to the authorities). These are too small and primitive to be likely to use railways or any other major equipment.

Karkar and Dudkash

There are hand-worked narrow gauge railways at the adjacent Karkar and Dudkash mines, which are situated about 12 km north east of Pol-e Khomri (also written Pulikhumri, etc) in central Baghlan province (Romanisation of the names vary: KarKar, DodDash, Dukash etc are used. Karkar and Dudkash are the versions used on a local signpost).3

Winches are used to pull loaded wagons out the mines 4 along inclines which are 120-320 m long with a gradient of 8-18 degrees.5

The winches are reported to have replaced “electric railcars”6 for hauling tubs out the Karkar mine.7

Once out of the mine, the wagons are pushed by hand to the end of the line where the coal is tipped out of the wagon on to a “huge black pile”.8

One of the railway tracks to a tip is now obstructed by a derelict Soviet tank (photo),9 and a diversion has been laid around it (photo).10 (Possibly a T-62 tank – but post-WWII Soviet tanks all look pretty similar to me. Can anyone give a positive identification?).

Locomotives

Some photos of Dudkash (such as the one below from the Ministry of Mines website) appear to show four yellow narrow gauge locomotives dumped at the entrance to the mine,11 though these machines are absent from more recent views.

Dumped mining locomotives just visible to the right of the entrance to the Dudkash mine (Photo: Ministry of Mines).

Could the Afghan locomotives be to ZTS Martin’s DH30 design, similar to this one in a museum in Slovakia? (Photo: Kris Ward).

There isn’t much to go on, but from comparison with photographs they are not unlike the DH30 design of Skoda-engined diesel-hydraulic mining locomotive produced by Czechoslovakian firm Turcianske Strojírne Martin in the 1970s and 1980s.12 There was Czechoslovakian involvement in developing the mines, so this would make sense.

This photo 13 dated 10 January 1970 (or is that a default date for old pictures?) shows a train emerging from the Karkar mine with what could be a locomotive on the front.

Location

View Coal mines in a larger map

From comparing various photographs of the two drift mines, I think the Karkar mine is the one with crossed hammers and painted dates above the mine entrance, while Dudkash has the double entrances and had a chip in the right-hand arch.

History

A shepherd discovered coal at Karkar in 1938, and production began the following year. Coal was initially loaded into bags and taken out by donkey.14 The coal mines branch of the Ministry of Mines was set up to develop the coal resources at Karkar and Dudkash, and at one time had 30 employees, 111 officials, 1667 contractors and 5 foreign experts from Czechoslovakia

. It was restructured as a government enterprise in 1971.15

From 195716 until 1988 the mine operated with assistance from Czechoslovakia, and used equipment supplied from the Warsaw Pact states.17 In addition to Czechoslovakia, experts from India and Russia also provided assistance.

Production peaked in the 1970s, with the Karkar mine employing 1600 people and producing 600-700 tonnes of coal per day before the Soviet intervention in Afghanistan. However virtually no capital investment was made in the mines after the Soviets left in 1989. The equipment fell into a very dilapidated state, with the mines being manual pick and shovels operations

. In 2004 Karkar had 318 staff and the four mines produced around 100 tonnes a day.18

In 2006-7 the four mines at Karkar, Dudkash, Ahandara and Khurdara mines and a cement works at Pol-e Khomri were privatised, with all movable and fixed assets transferred to the private Afghan Investment Company in April 200719 20 The mines are now operated by AIC subsidiary Afghan Coal LLC, providing fuel for AIC’s cement plant and a proposed 25 MW thermal power plant.21

Dudkash mine entrances after modernisation (Photo: Afghan Investment Company)

Photos of the coal mines in the 1980s

Links

- Lots of photos from Time taken in October 2004.

- Photos from Life

- More photos, by Patrick Andrade (under See the Pictures > Afghan mine – nice pictures but the navigation is a bit odd).

- Photos by Beb C Reynol taken in 2005.

- There are photos at World Picture News taken by Jean Chung on 5 December 2006 and Jared Moossy on 16 July 2007. Try searching for

afghan coal mine. - In pictures: Afghanistan’s mines, BBC, Tom Coughlan with photos by Veronique de Viguerie.

- Video of the railway in action. Keep going to the end for the tippler in action (and an abandoned tank).

References

- Mining, Afghan Chamber of Commerce ↩

- Assessing the Coal Resources of Afghanistan, US Geological Survey, 2005 ↩

- Paula Bronstein/Getty Images photograph no.51631164 dated 30 October 2004 ↩

- World Picture News photos 336604, 336650 ↩

- Report No. 28231-AF Transitional Islamic State of Afghanistan Mining as a Source of Growth, World Bank, March 2004 ↩

- Assessing the Coal Resources of Afghanistan, US Geological Survey, 2005 ↩

- Coal Mining in Karkar, Afghanistan’s Most Active Coal Mine, Paula Bronstein/Getty Images, Life, 31 October 2004 ↩

- Inside a crumbling Afghan coal mine, Quentin Sommerville, BBC News, Pul-e Khumri, 25 June 2010 ↩

- see picture 10, PatrickAndrade.com ↩

- The Cost of Coal in Afghanistan, Beb C Reynol, Delta Geographic, 2005 ↩

- see picture 2, PatrickAndrade.com and picture 1173470 at World Picture News ↩

- DH30 D.0, Ivo Novotný, Spolecnost Barbora, 28 August 2006 ↩

- photo no.51959377, AFP/AFP/Getty Images, 10 January 1970? ↩

- Amid Reconstruction Efforts, Afghanistan’s Largest Coal Mine Rusts Away, Patrick Andrade, EurasiaNet, 26 January 2006 ↩

- Northern Coal Enterprise, Ministry of Mines ↩

- A snow-covered coal tipple at Karkar Coal Mine 5 December 2006 (text and photo are from World Picture News) ↩

- Amid Reconstruction Efforts, Afghanistan’s Largest Coal Mine Rusts Away, Patrick Andrade, EurasiaNet, 26 January 2006 ↩

- Report No. 28231-AF Transitional Islamic State of Afghanistan Mining as a Source of Growth, World Bank, March 2004 ↩

- Northern Coal Enterprise, Ministry of Mines, Afghanistan ↩

- Minister’s press confrance on 21/8 1386, Ministry of Mines, Afghanistan, 12 November 2007 ↩

- Afghan Coal LLC, Afghan Investment Company ↩